Left unchecked, concrete and asphalt debris can overwhelm local landfills, squander valuable aggregate resources, and dramatically worsen the building sector’s environmental footprint. Construction waste is among the largest contributors to landfill volume in many countries. With every ton of landfill-bound debris, opportunities for salvaging reusable material—thus reducing raw resource extraction—are missed. By prioritizing creative and sustainable techniques, contractors dramatically improve how this waste stream is handled, cut overall project costs, and promote a greener, more innovative future for the whole industry.

The ever-evolving landscape of construction has brought both remarkable advancements and significant challenges. Among the most pressing challenges is the responsible management of construction waste, particularly concerning concrete and asphalt materials. As cities expand, infrastructure ages, and projects become more complex, finding efficient and sustainable solutions for concrete disposal has grown critical—not only for developers and project managers, but for the environment and urban communities. The cumulative impact of poor disposal practices can devastate local ecosystems, air quality, and even public health when contaminants leach into groundwater.

Recycling Concrete and Asphalt: Environmental and Economic Benefits

Large-scale concrete and asphalt recycling is a cost-effective way to reduce construction waste. This process not only diverts debris from landfills but also safeguards finite resources like sand and gravel. On-site recycling also helps companies cut project costs by reducing material purchases, hauling debris to disposal sites, and landfill tipping charges. This eco-friendly and operationally efficient approach supports business goals and promotes sustainable practices in the construction industry. Public works contracts often require a certain percentage of recycled aggregate, giving firms a competitive edge.

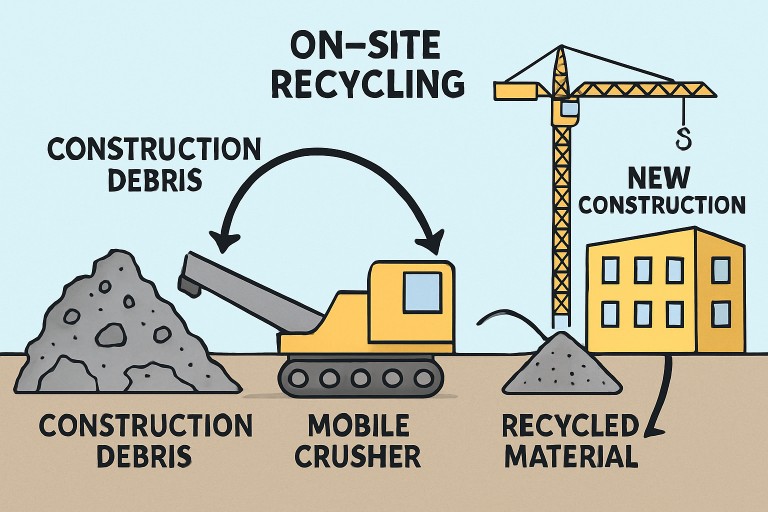

On-Site Processing Techniques

On-site waste processing can improve project logistics and construction sustainability. Two techniques are rubblization and mobile crushers. Rubblization involves breaking down existing concrete and creating a stable base for new roads or buildings. This eliminates the need for large slab removal and expedites redevelopment timelines. Mobile crushers quickly process concrete and asphalt debris, reducing transportation costs and emissions. This also allows for processing material reuse, reducing delays and improving efficiency. These techniques can be scaled to handle various projects, enhancing logistical flexibility and waste reduction efforts.

Innovative Materials and Technologies

Construction teams are adopting environmentally responsible alternatives to concrete and asphalt disposal. Carbon-sequestered asphalt, incorporating carbon captured from industrial processes, offers high strength and long service life while capturing greenhouse gases. Municipalities like New York City are piloting these sustainable alternatives. Recycled aggregates are also being used in concrete mixes, reducing reliance on freshly mined aggregate and promoting the circular economy. These innovations help meet the industry’s ecological standards, performance, and durability expectations.

Collaborating with Recycling Facilities

Collaborating with recycling facilities is crucial for responsible waste disposal in construction projects. These centers use industrial crushers, graders, and sorting technologies to process waste into high-quality secondary materials. This ensures compliance with local regulations and builds transparency through clear documentation. Contractors and project managers can report recycling rates, earn green building credits, and demonstrate environmental stewardship. Working with recycling centers is mandatory in some regions for government or LEED-certified projects.

Implementing Sustainable Practices

To promote sustainable concrete and asphalt disposal, construction managers should conduct a comprehensive waste audit at the start of each project, develop a robust waste management strategy, provide ongoing training for site staff, and establish partnerships with local recycling facilities. These steps help contractors meet regulatory requirements and foster a culture of sustainability throughout the construction process. More firms are documenting their successes in recycling concrete and asphalt, using this documentation to support grant applications, marketing campaigns, and recruitment efforts. This approach will help reduce waste and maximize recycling in the construction industry. For additional best practices and more detailed guidelines, industry professionals can review resources from the U.S. Environmental Protection Agency.

Conclusion

The construction industry is moving towards more responsible practices by embracing innovative and collaborative approaches. These include creative concrete disposal strategies, advanced on-site processing technologies, and partnerships with recycling experts. These not only enhance project outcomes but also reduce environmental impact and build resilient infrastructure. Strategic material management is crucial for a cleaner build and a more sustainable industry.