Cement serves as the backbone of construction projects worldwide, providing the binding agent that holds structures together. However, the quality of cement can vary significantly, posing risks to the durability and safety of buildings and infrastructure. Cement testing plays a crucial role in assessing its properties and ensuring compliance with industry standards. Yet, achieving standardization across testing methods remains a challenge, impacting the reliability of results and, consequently, the quality of construction projects.

Understanding Cement Testing Challenges:

Diverse Testing Methods:

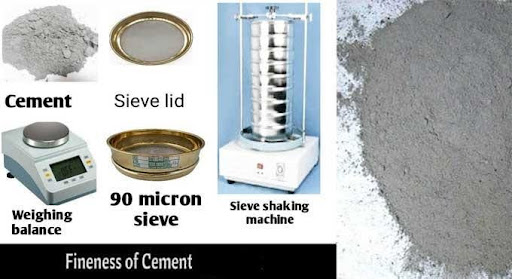

cement tests involve a multitude of methods aimed at evaluating various properties, including strength, setting time, fineness, and chemical composition. However, the absence of uniformity in testing protocols can lead to discrepancies in results, making it challenging to compare data accurately.

Lack of Standardization:

The absence of standardized testing procedures across different regions and regulatory bodies complicates the assessment of cement quality. Varying standards and methodologies create confusion and hinder efforts to establish consistent benchmarks for evaluation.

Technological Advancements:

The evolution of technology has introduced innovative testing techniques, promising more accurate and efficient assessments of cement properties. However, integrating these advancements into existing standards and practices poses logistical and regulatory challenges.

Harmonizing Cement Testing Methods:

Collaboration and Knowledge Sharing:

Industry stakeholders, including manufacturers, regulatory agencies, and research institutions, must collaborate to develop standardized testing protocols. Sharing knowledge and best practices can streamline the standardization process and foster a collective understanding of effective testing methodologies.

Alignment with International Standards:

Adopting internationally recognized standards, such as those established by organizations like ASTM International and the International Organization for Standardization (ISO), can promote consistency in cement testing practices. Harmonizing with global standards enhances credibility and facilitates cross-border trade of construction materials.

Continuous Improvement and Adaptation:

The dynamic nature of construction materials necessitates ongoing review and refinement of testing methods to keep pace with technological advancements and industry trends. Regular updates to standards ensure relevance and accuracy in assessing the quality of modern cement formulations.

Data Transparency and Traceability:

Implementing systems for transparent data collection and traceability enhances accountability and reliability in cement testing. By documenting testing procedures and results in a standardized format, stakeholders can track the quality of cement throughout its lifecycle, from production to application.

Education and Training Programs:

Investing in education and training initiatives for laboratory technicians and industry professionals fosters proficiency in standardized testing methods. Continuous learning opportunities empower personnel to stay updated on evolving standards and best practices, ensuring proficiency in conducting accurate and reliable tests.

Industry-wide Quality Assurance Programs:

Establishing industry-wide quality assurance programs encourages adherence to standardized testing protocols and fosters a culture of excellence in cement production and testing. By incentivizing compliance and excellence, such programs promote consistency and reliability in the assessment of cement quality.

Research and Development Initiatives:

Investing in research and development initiatives facilitates the exploration of innovative testing methodologies and technologies. By staying at the forefront of scientific advancements, the industry can improve the accuracy, efficiency, and reliability of cement testing, driving continuous improvement in quality standards.

FAQs:

Q: How do inconsistent testing methods affect construction projects?

A: Inconsistent testing methods can lead to unreliable data, compromising the structural integrity of buildings and infrastructure. Variations in cement quality may result in defects, reduced durability, and safety hazards.

Q: What role does certification play in cement testing?

A: Certification ensures that testing laboratories adhere to recognized standards and guidelines, enhancing the credibility and reliability of test results. Certified materials testing products, such as those offered by Certified Material Testing Products, guarantee quality assurance in cement testing processes.

Conclusion:

The standardization of cement testing methods is essential for upholding quality standards in the construction industry. By addressing the challenges associated with diverse testing techniques and promoting harmonization efforts, stakeholders can enhance the reliability and consistency of cement evaluations. Companies like Certified Material Testing Products play a pivotal role in this endeavor by providing high-quality testing equipment and supporting the implementation of standardized practices.