Logistic straps are everywhere from moving trucks to cargo ships and the right end fittings make all the difference in keeping your load secure. These small but powerful parts connect the straps to anchor points, ensuring your cargo stays put no matter how bumpy the ride.

But with so many types of end fittings out there, it can get confusing. In this guide, you’ll learn how to spot each type, understand what they’re best for, and use them safely. That way, you can handle your logistic straps like a pro every time.

What Are Logistic Straps and Why End Fittings Matter

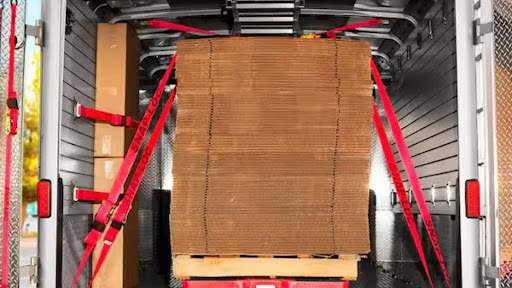

Logistic straps are essential tools used to keep cargo safe and secure during transport. Whether you’re moving furniture, loading pallets on a truck, or tying down equipment, logistic straps help hold everything in place.

But just as important as the straps themselves are the end fittings; the metal or plastic parts that connect the strap to the anchor points. Without the right end fittings, even the strongest strap won’t do its job well.

What Are Logistic Straps?

Logistic straps are strong bands made from materials like nylon or polyester. They are designed to stretch a little and hold tight, keeping your load from shifting or falling. These straps come in many lengths and widths, depending on what you need to secure. They are commonly used in trucks, trailers, and warehouses.

Why End Fittings Are Important

End fittings are the connectors on the ends of logistic straps. They attach the strap to hooks, rings, or other anchor points on vehicles or storage areas. These fittings must be tough enough to handle heavy loads and hold securely under pressure. If the end fittings fail, the entire load could shift or fall, causing damage or injury.

How End Fittings Help With Safety

End fittings not only connect the strap but also make it easier to fasten and release the strap. Different types of fittings work better with different anchor points, so choosing the right one is key. For example, a hook fitting might grab onto a metal loop, while a flat hook might fit better on a flat surface.

Different Types of End Fittings Explained

When working with logistic straps, knowing the different types of end fittings is important. These fittings connect the strap to your anchor points and help keep your cargo secure.

Each type of fitting has its own shape and function, making some better suited for certain jobs than others. Let’s break down the most common end fittings you’ll come across.

Hooks

Hooks are one of the most popular end fittings on logistic straps. They come in different shapes like S-hooks and J-hooks.

- S-Hooks have a simple curved shape that easily hooks onto anchor points like chains or loops.

- J-Hooks have a tighter curve, which gives a stronger hold on anchors that aren’t very thick.

Hooks are easy to use and great for quick fastening.

Claws and Grabbers

Claws and grabbers are designed to grip onto edges or flat surfaces. They have teeth or serrated edges that hold tight when you pull the strap. These fittings are helpful when you don’t have a loop or ring to hook onto. Just make sure they’re secured properly so they don’t slip.

Flat Hooks and Snap Hooks

- Flat hooks have a flat surface that lays against the anchor point. This shape reduces wear on the strap and works well on flat metal surfaces or rails.

- Snap hooks come with a safety latch that closes over the hook opening. This latch prevents accidental release, making snap hooks a safer choice when the strap needs to stay firmly attached.

Rings and Loops

Some logistic straps use rings or loops as end fittings instead of hooks. These fittings allow the strap to be threaded through or attached with other connectors. Rings are simple and versatile but need to be paired with the right anchoring system.

How to Identify End Fittings on Your Logistic Straps

Knowing how to identify end fittings on your logistic straps is key to using them correctly and safely. End fittings come in various shapes and materials, and spotting the right one helps you match the strap to your load and anchor points. Here’s a simple guide to help you recognize the common types.

Look at the Shape

The easiest way to identify end fittings is by their shape. Hooks, for example, usually have a curved design like an “S” or “J.” Flat hooks have a wide, straight surface, while claws and grabbers look like small claws with teeth. Rings and loops are round or oval and don’t have an open hook.

Check the Material

Most end fittings are made from metal like steel or aluminum because they need to be strong. Some lighter fittings may use plastic, but these are usually for lighter loads. The material often tells you how much weight the fitting can handle.

Find Load Ratings and Markings

Many logistic straps and their fittings have stamped numbers or labels showing their load capacity. These numbers tell you the maximum weight the fitting can safely hold. If your strap has a label, check it before using to avoid accidents.

Inspect for Safety Certifications

Some fittings come with safety certifications from organizations that test how strong they are. Look for tags or markings that show the fitting meets certain safety standards.

Check for Wear and Damage

Identifying fittings also means inspecting them for damage. Look for cracks, rust, or bent parts. Damaged fittings can fail during use, so replace any that look worn out.

Tips on Utilizing End Fittings Effectively for Safe Cargo Securing

Using the right end fittings properly is key to keeping your cargo safe during transport. Even the best logistic strap can fail if its fittings aren’t used correctly. Here are some easy tips to help you get the most out of your end fittings and secure your load safely.

Match End Fittings to Your Anchor Points

Not all end fittings work with every anchor point. Make sure the hook, ring, or claw fits snugly on the part you’re attaching it to. For example, use S-hooks on chains or loops and flat hooks on smooth surfaces. A good fit means less chance of slipping.

Attach Straps Securely

When fastening, pull the strap tight but don’t overdo it. Too much force can damage the strap or fittings. Also, make sure the fitting is fully hooked or latched before moving. If you’re using snap hooks, check that the latch is closed properly.

Inspect End Fittings Regularly

Before every use, look over your fittings for cracks, rust, or bending. Damaged fittings can break under pressure, causing accidents. Replace any worn or broken parts right away.

Store Straps and Fittings Properly

After use, keep your logistic straps and fittings clean and dry. Store them in a cool, dry place away from direct sunlight. This helps prevent rust and material wear, making your fittings last longer.

Use Safety Features When Available

Some fittings have safety latches or locking mechanisms. Always use these features when they’re available. They add an extra layer of security and help prevent accidental release during transport.

Conclusion

Knowing how to identify and utilize the various end fittings on logistic straps is key to safe and efficient cargo securing. By choosing the right fittings and using them correctly, you protect your load and yourself. Keep your straps and fittings in top shape, and you’ll secure your cargo with confidence every time.