Automatic slitting machines allow modern packaging businesses to save time and money while improving production efficiency. In the contemporary world of packaging, automatic slitting machines are an indispensable part of nearly any slitting machine provider’s catalog. There are many advantages that modern packaging companies gain with the use of automatic slitting machines. As slitting machine manufacturers continue to innovate, automatic slitting machines have become more reliable, efficient, and cost-effective. This article seeks to analyze the importance of investing in automatic slitting machines in the contemporary cut throat packaging business.

What is an Automatic Slitting Machine?

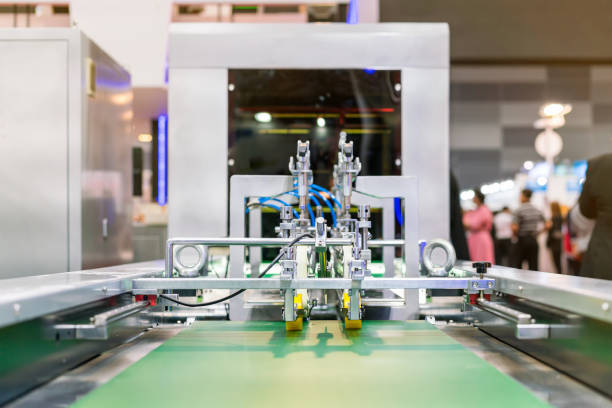

An automatic slitting machine is a device that separates a wide parent roll of material into strips or smaller rolls of several different widths. These machines are commonly used in the packaging industry to cut paper, plastic films, aluminum foils, and also textiles used for packaging. The process of the machine working involves feeding a parent roll into the machine where it is unwound, moved into the blades or cutters, and then wound back into smaller segments.

The functioning of automatic slitting machines is both precise and rapid, which allows manufacturers to produce materials that are of uniform quality and size necessary for processes like printing and packaging that follow. In its role as a leading manufacturer of slitting machines, KETE has been pioneering the development of advanced machines that are optimized for performance and productivity. These machines are also used in a variety of applications from food to industrial packaging, thus having great scope of applicability. Through higher levels of automation, slitting machines increase automation consistency, reduce chances of human error, and make the process of cutting more straightforward. Compared to automatic methods of cutting materials, manual techniques tend to take a lot longer, require more work, and are more likely to make mistakes. At the same time, automatic slitting machines operate at a higher speed, and can transform big rolls into narrower rolls of material in a shorter period of time.

Enhancing Production Speed and Efficiency

These automatons work at an unmatched speed, enabling businesses to enhance production when there is an increase in demand. Further, KETE’s automatic slitting machines make use of modern automation features, which increases precision as well as reduces the time taken on setup and quality assurance. Moreover, features such as automated blade changes and remote-controlled adjustments ensure that even the most intricate cuts on materials are performed in minutes, greatly reducing downtime. Such efficiencies translate to improved production and an increasing number of orders being met in a shorter time frame, thereby improving the business’ capability to respond to stringent deadlines and rising market expectations. Further, the use of energy is also optimized, which helps in saving money as well as enhances the productivity of the business operations.

Reducing Material Waste and Maximizing Yield

Automatic slitting machines give greater yield and waste less material, making them much more efficient. Unlike KETE machines, other cutting devices require inefficient manual methods which cause either mistakes in cuts or gaps between the slices.

Manufacturers can guarantee that every roll of material is utilized effectively thanks to the precise cuts provided by slitting machines. The cuts can be made at varying widths and precise measurements, which ensures that the minimum possible scrap material is produced. That results in lower expenses for materials and a higher efficiency in the use of raw materials. Moreover, businesses are able to become environmentally friendly by lessening their waste by using scratch materials. To help businesses, KETE’s slitting machines are a perfect example, as they are made with high-quality blades and precise tension control which improves yield while simultaneously reducing waste, making them the ideal investment for companies aiming to reduce costs while improving sustainability. By making these adjustments, businesses are also able to reduce the carbon footprint of their packaging operations, which contributes to meeting corporate sustainability goals.

Shifting Focus from Sustainability to Flexibility and Customization

The great thing about automatic slitter machines is that they offer a range of flexibility and extensive customization features which makes them perfect for an array of packaging materials and applications. Regardless whether a business deals with paper, plastic films, foils or textiles, automatic slitting machines can be modified for different materials as well as production requirements.

Additionally, these machines can be modified to consider production requirements like roll width cutting, thickness, and speed. Such flexibility guarantees that KETE’s clients in the packaging business are able to offer various sizes and configurations of packaging materials to different clients. This flexibility extends beyond the capabilities of automatic slitting machines, enabling businesses to swiftly pivot in response to shifting market changes or customer needs. With the increase in consumer needs and the specialization in packaging, KETE’s slitting machines give the capability to change to new projects or product specifications with little turnaround time and no costly retooling processes. Therefore, businesses are able to target new markets while enhancing their productivity efficiency.

Conclusion

To conclude, automatic slitting machines have numerous advantages to modern packaging businesses. From remarkable production speed and enhanced precision to less labor and efficient material usage, these machines have become an integral part of modern approaches to packaging. The more innovative slitting machine producers become, the more advanced the features of automatic slitting machines will be for businesses in need of modern solutions for their packaging, and the greater their capabilities will be.

KETE’s constant innovation provides these firms with the capabilities to adopt advanced sustainable approaches in productivity as well as customer satisfaction while achieving greater environmental and economic efficiency in response to these emerging packaging demands.

Integrating automatic slitting machines within their production lines helps these companies boost efficiency, minimize expenses, and maintain quality. Such investment is strategic for firms in the packaging segment seeking seamless operations and increased profits in future periods. These machines ensure the precision and flexibility required by the dynamic environment of the packaging sector, which means businesses can stay relevant and prepared to meet future changes.